Deviation Actions

Description

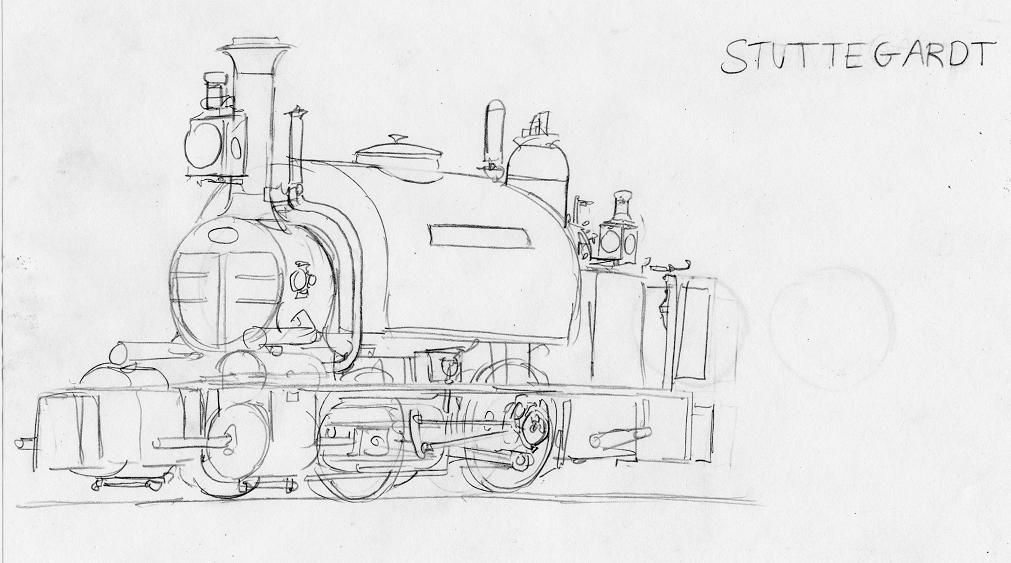

In later years, many locomotives on both the long inclined plane of the slipway, on long hill-railways, lines with steep inclines, or exceptionally fast and developed steam locomotives, would come to use this innovative system of dynamic braking.

The counter-pressure braking system is not to be confused with the counter-steam method of braking a locomotive, which involves simply reversing the valve timing while moving in one direction. This practice can overtime cause damage to the valve spindles of slide-valve engines, and can completely destroy the valve and pistonrings of piston-valve locomotives. It will also most assuredly have the capacity to destroy the exhaust poppet valve spindles and follower cams of poppet valvegear of any type.

For a friend.

I don't think the idea of "steam dynamic brake" would work good.

First of all, I see no reason to send steam to the brake system. I highly doubt air brake would love condensed water inside the brake line. It would make much more sence to just temporarily turn a steam engine into a large pump without any water injection.

Secondly, dynamic brakes are used mostly in regions with a complicated gradient where they have to be applied oftenly. In case of a steam engine, that would lead to cylinders being constantly cold sufficiently increasing condensing losses rendering locomotive uneconomical due to increase of specific steam consumption per horsepower. It would be like cold starting a locomotive each time.

Thirdly, powerful brake force of combined "dynamic" and conventional brake can lead to drivers stopping their rotation creating an undesired wheelslip and sufficient damage to driver rims increasing maintenance cost and time.

Fourthly, using cylinders as a big pump has the same problem as a counter-steam - increased forces on coupling rods and their connection to the wheel (hence quick wear and a probability of some important parts of mechanism breaking down). This becomes a serious problem if the usage of such mode is often.

Fifthly, it would simply make cylinders unnecessary complicated increasing maintenantce troubles even more.

Cheers!